Mechanical Engineering Technology

Program Type: Associate In Applied Science

Program Level: UG

Division: Career & Technical Education

Program Duration: 24 months

Program Contact: David Edwards

Credit Requirement: 64

Time: Day

Program overview

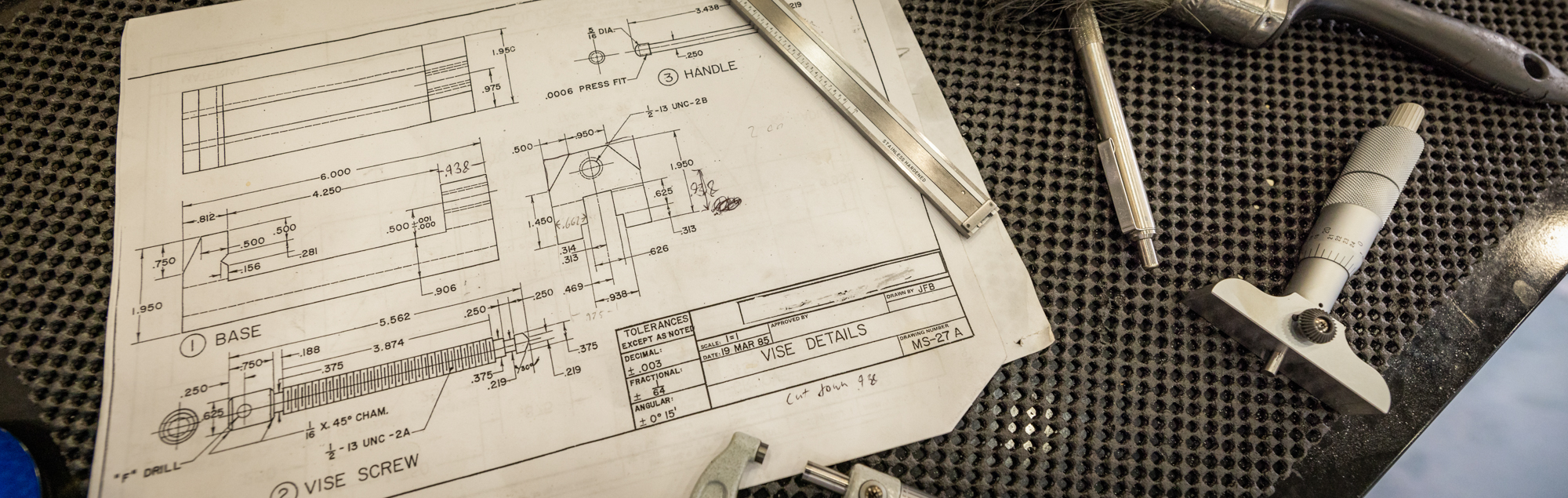

The Mechanical Engineering Technology program (MET) uses classroom and laboratory experiences to prepare graduates to work as engineering technicians and related engineering technology positions in various industries and production facilities. The intent is broad-based education that gives the student a number of career choices.

Courses Required

- Choose an option

Entry Requirements

To see a list of entrance requirements for this program, please check the FDTC Course Catalog.

Student Learning Outcomes

Graduates of this program will be able to:

- Build, test, and troubleshoot fundamental hydraulic and pneumatic systems. Students will characterize pertinent system parameters to include pressure, force, area(s), displacement, and flow. Students will build PLC programs and integrate into pneumatics systems to meet production specifications.

- Model a basic machine system and characterize pertinent mechanical parameters to include mechanical advantage and work done. Students will investigate mechanical efficiencies and optimize processes to meet specifications.

- Utilize 2D CAD software to delineate part details and produce documentation to enable accurate production. Students will employ 3D CAD software tools to create both part and assembly models and employ simulation software to characterize mechanical systems and to convey both design concepts and detail to both technical

and non-technical personnel. Students will produce competent prototype models and evaluate form and fit within assemblies. Students will iterate prototype model production and demonstrate model and prototype improvement techniques to meet customer demands. - Interface with basic automation and robotic systems. Students will create specific task programs to accomplish tiered pick and place operations. They will troubleshoot operational errors to ensure proper program operation.

- At program completion, students will build, test, and characterize fundamental electrical circuits. Students will apply learned PLC programming concepts and practical circuit knowledge and integrate into electromechanical systems to meet production specifications.